This is a reproduction of the final project report submitted as part of my degree in Industrial Design. The contents for the most part have remained the same as the original paper and was relevant in the context of the time it was written. Therefore it may or may not contain discrepancies in content when applied to today's standards and developments. Originally written in June 2014.

Design Problem

Background

In 2010 number of people living in urban areas was 249,253,271 people. This accounted for 80.7% of the US population, which in total encompasses only 2-3% of US soil (US Census Bureau, 2010a, 2010b, 2010c). Population growth and urbanization have become major issues for city planners as living space becomes ever smaller. Housing beyond city limits alleviates some of this problem but brings along issues of creating adequate transportation infrastructure in and out of the city. Japan with its limited amount of land have partially overcome this problem with micro-dwellings. As a result, the US is looking at these miniature sized apartments as a solution to its ever growing urban population (Mayor Bloomberg, 2013).

Micro-dwellings or more specifically micro-apartments are living spaces made in very small spaces, typically under 150-350 ft2 / 14-32.5 m2 although some extreme examples can be compared to a large closet (Mukherji, 2014). In the US, many major cities such as Seattle, Denver, and New York are already expressing interest in the micro-apartment concept (Koch, 2013). With such potentially limiting floor space, amenities within the household are often simplified and reduced to save space. In these small living spaces, the bath is often replaced by a shower as it takes up less space and is quicker than a bath, ideal for a fast paced urban lifestyle. That said, bathtubs do have their own advantages that a shower is unable to provide such as stress relief and relaxation. A space saving bath is what is needed to bring the bath back to these small abodes.

Bathtubs come in various sizes and configurations. From Sitz baths where the user essentially sits in a bucket of water to the grandeur of the modern Jacuzzi bathtubs, baths have been reshaped and remodelled to suit the needs of their users. The Japanese have had a long relationship with bathing, with a distinct bathing culture focused on relaxation. Because of this, traditional Japanese baths are designed more similarly to a hot tub with bathtubs like the Furo being taller but shorter in length with users sitting in the bath rather than laying down. A convenient space saving concept that has adapted well to small spaces of urban Japanese homes.

In the west the idea of a space saving bath is not a new one and with portable, foldable baths made of oilcloth and wood frames being built as far back as the 1880’s (Coleman, 1994). To narrow down the variety of different size bathrooms, this project is set around the My Micro NYC project in New York; a project aimed at testing out these micro-apartments for New York, undermining the city’s current building code for minimum living space (mayor Bloomberg, 2013). For this project, the aim will be to design a bath to fit within a micro-apartment bathroom, using the bathrooms of the MyMicroNYC project as an upper size limit.

Needs and Requirements

The current market for the new housing units are young households, consisting of one or two people within the age range of 20-35 years old. They will be initially installed in the bathrooms of the My Micro NYC with the excess units sold retail. It is important that the design caters to the users fast paced urban lifestyle as well as its function of a bath. The size limitations of the micro-apartments mean that the footprint of the unit becomes critical in the overall design of the unit. What this means for the bath is that is that it must be as compact as possible and ideally smaller than the size of a standard bath. However the size of the bath must still be able to accommodate the majority of its potential user base. The 95th percentile of the US population became the upper limit to which this unit is designed for.

Performance requirements are not numerous for a bathtub and are not critical to the functionality of the bath. Water flow and water drainage will typically be determined by the quality of plumbing at the installation site. However the other performance benchmarks needed to be considered. For example the bath materials needed to have insulating thermal properties to minimize heat loss. Other factors such as the chemical resistance and ease of maintenance were also considered. One key factor was the degradation rate of the bath, particularly with any organic material used. Any organic material needed to be rot resistant to ensure parts last throughout the products lifespan. As rot resistant woods rely on their oil content to resist rot, it is important that the material used is not an irritant, or minimizes the risk. Considering the small area in which the unit is to be installed, the design of the bath was aimed to be largely self-contained in order to maximize the ease of installation by minimizing the amount of preparatory work needed in the bathroom.

Production quantities are to be kept low, a batch production of around 400 units. It is estimated that based on 2010 population data, 80.7% of the American population live in urban areas (Statistical Abstract of the United States: 2012, 2012). Of this, it is taken that 36% of the population is within the target age brackets (Lofquist, Lugaila, O'Connell and Feliz, 2012). With 6% of households renovating their bathrooms this leaves a market size of 1.4% of the total US population (Renovation in America, n.d.). Localizing this to New York gives a market size of around 9700 households who may potentially refurbish their bathroom in the near future. However, as most of these households are not micro-apartments, the target is to acquire 0.05% of this market and slowly introduce the product with development of micro-apartment projects.

Design Process and Solution

Design Process

The design process for this project revolved heavily upon secondary research along with form and spatial studies. Initial study was focused around the definition of a bathtub based on its deconstructing its mechanical function and shape. This deconstruction allowed for the identification of its core features and requirements, defining the limits of the contemporary concept of a bath. A substantial amount of research was also focused on existing micro-dwellings, to allow for a firm grasp on the type of environment the end product would be in. Urban Japan has prominently featured micro-dwellings and provided insights into space saving solutions already implemented.

Japanese micro-apartments and culture became a key part in the research and driving forces of the project. The aesthetic drive stemmed out of the Japanese approaches to design while utility focused and practical served as intrinsic drivers. Initial concepts were spawned from sketch studies of existing bathtub designs and the redesigning of features to suit the micro-bathroom. These concepts proved limiting in their scope so the adoption of themes and shape studies were used. Some themes were a derivative of initial concepts while others were selected based on their associative relevance (such as origami) or irrelevance (such as abstract shapes) to the core design philosophy of the project.

A major part of the design process was in the consideration of space within each design. To understand the amount of space needed for a bathtub, additional studies were conducted to explore space usage of both bathtubs and showers. Through the construction of scale models and the space studies, the concept of a bath that folded or moved was developed. However as the design continued to be refined, several design problems inherent to the concept resulted in drastic changes to better accommodate the driving forces of the project. Consequently the design was then simplified to still combine the advantages of the initial design but without complex moving parts.

During the time the folding bath was considered, the design revolved around the concept of a heavily modified wooden bath, similar aesthetically to the Furo. To understand the different effects that a wooden bath could give, multiple material samples were obtained and wooden bowls of various sized were used as aesthetic and functional proofs of concepts. Mechanical proofs of concept models were also made to explore the different methods of folding away a bathtub. To facilitate the folding, flexible materials such as silicones, rubbers and plastic polymer sheets were sourced to determine their suitability to the application. Although the information obtained through this process was largely discarded in the final design, the study provided insight into the properties and limitations of a folding bath.

Design Solution

SIRNA II

The Sirna II was an evolution of the previous Sirna design based on the shortcomings found during detailed development. The original design had problems within the design of the deployment mechanism, with the bath taking form of a solid hardwood panel, the weight and ease of use of the bath were compromised as the thick panel would have been be unwieldy to handle or require mechanical assistance, complicating the design and maintenance of the bath. Aesthetically the design was lacking as well and with mechanical and ergonomic limitations to be considered, it proved difficult to enhance the aesthetic without resorting to superficial or superfluous solutions.

The final design discards the moving bath panel of the original and opts for a combined fixed positioned bath and shower. In regards to the design spec, a key aspect of the design requirement was the minimalizing of the bathtub footprint. It occupies a floor space of 1.1m by .75m, roughly the size of medium sized shower enclosure with a bathtub similar in proportions to the Japanese Furo bathtubs. The top half is an enclosed shower unit with an integrated corner seat and access is provided through a Dutch style door.

One part that is a relative departure in the design is the lower door. While most of the unit is vacuum formed acrylic and wood, the door is made of rotational molded PVC. The bathtub itself is manufactured in black acrylic obscuring much of the visual detail within the bath creating the impression of a larger space when viewed from within. Although the difference in material creates a incongruence in appearance and texture, the cost advantages of being able to mold specific door features to accommodate door fixtures mean that the difference is negligible compared to its benefits. And with similar coloration of the material, the visual differences are further negated.

To provide the best water resistance, Western Red Cedar was chosen for the wooden parts, a highly rot resistant timber. Cedar was chosen to emulate the feel of traditional furo bathtubs and Japanese bathhouses which would prominently feature Hinoki Cedar. The Red Cedar also has the additional benefit of being widely available in northern America and not prone to causing allergic irritation (Wood-database.com, n.d.).

Because the original design had a lengthy user trip to set up the bath that required a lot of space, the removal of the kinetic aspect allowed for a smaller overall footprint. The furo-esque bath, possessed a smaller footprint than the original design with the bath deployed and lack of kinetic components meant the user trip could be reduced alongside its footprint. Creating more static elements within the unit also allowed for aesthetic improvements.

CAD Production

For the design and visualization of this project, the Solidworks and Photoview CAD packages were used. Their entrance into the design process began at the point the initial Sirna concept with the moving parts was selected. Within these initial stages, Solidworks was used mainly as a visualization aid to determine size proportions relative to the bathroom environment. During the detailed development stages, Solidworks also served as a test platform for the analysis of the moving parts in the bath using “mates” on 3D features or by using 2D sketches with variable relations allowing movement of sketch elements. This process served to limit the distance, angle and height of the moving parts and judge the mechanical feasibility of the design. This testing was applied on the main extending panel on the initial concept and on the doors in the final design.

Design for User

Solidworks also helped in the designing of parts around the human body. Using anthropometric data, various parts were designed and altered to accommodate both the proportions of the body and the aesthetics of the design. Key areas that benefited from this process were the seat, the bath and the doors. Initially the doors spanned 400mm across based on it aesthetic appeal. However according to the anthropometric data from NASA (1995), the width of the shoulders for the American male ranged from 488mm to 615mm from the 5th to 95th percentile. As a result, the door was widened to 500mm. With a chest depth of 282mm for the 95th percentile of the American male, this allowed the lower range to be able walk directly in and the upper ranges to enter through sidestepping. Similar considerations were given in regards to the size of the seat and the bath in relation to the proportions of the legs, buttocks and height.

The seat used the sketch tools to good effect by allowing ad hoc adjustments. In the NASA (1995) data, the length of the buttocks to the knees spans 658mm. This would be the ideal size for an ergonomic seat, but due to size restrictions it had to be reduced for the seat in the bath unit and the seat was eventually reduced to a radius of 300mm. Alternate sizes and configurations were also considered but would result in inefficient use of space, an obstruction to sitting down in the already small bath or as a visual detraction. As a result, the small seat functionally performs more as a perch to sit on rather than a fully ergonomic seat.

Design for production

All wood Japanese ofuro & bathroom (Black & Murata, 2000)

There were also design decisions made with consideration to the production and manufacturing of the unit. The bathtub and the outer side panels were designed as a vacuum formed parts and as such, draft angles were incorporated into the design by chamfering all sides of the bath by two degrees to ease tool ejection. None of the vacuum formed parts take into account the variance in material thickness in the walls as the form is pulled. The parts were designed as representative parts with crucial measurements highlighted for the toolmaker and the stretching of the material compensated by the thickness of the original blanks.

The design of the bath frame was made of 20mm square steel tubing. To simplify the design of this frame, rather than extruding individual pieces and mating a series of separate parts together, the weldment feature was used. The weldment feature allows for a wireframe 3D sketch to be used to create a welded frame. This tool automatically models the extruded solids and arranges them on the 3D sketch while simultaneously creating a cutting list, listing the lengths of tubing required.

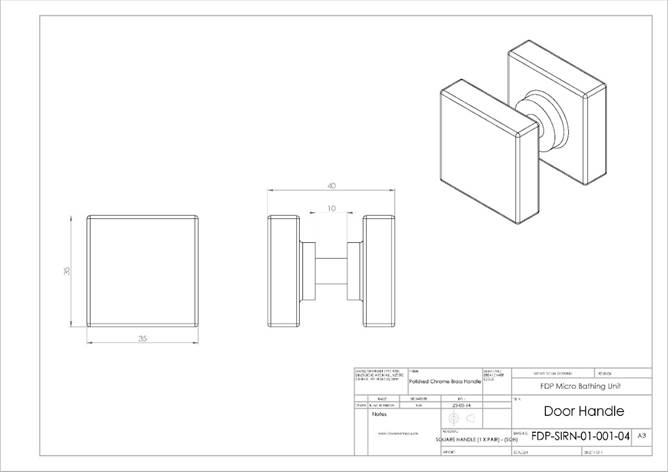

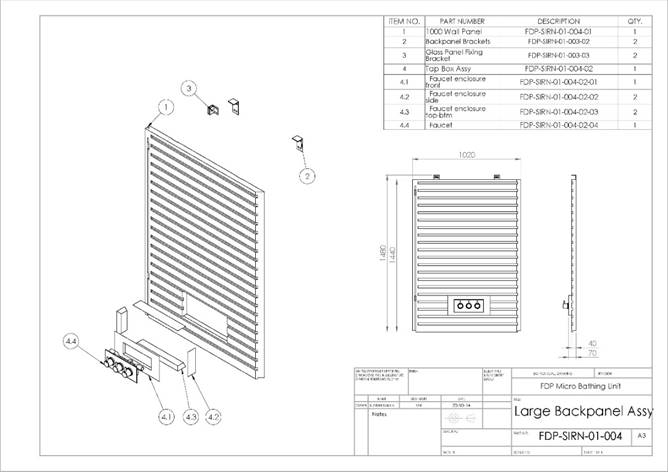

The final design also included off the shelf components. These parts were duplicated by using drawings available through the manufacturers and installed onto the model. Other fixtures such as brackets were designed as bespoke parts. To prevent distracting from the aesthetics, the fixings within the unit were to be largely hidden away. Brackets to fix the side panels to the walls without exposed screws were hidden away by the header panel. Brackets that hold the glass panels in place were also hidden away preserving the aesthetic integrity of the enclosure.

Rendering and visualization

The initial concept lacking significant aesthetic character and drive, it presented itself in a poor manner during initial rendering tests. To enhance the visual appeal of the design, the initial concept was visualized within a bathroom scene using prop assets available in the public domain to furnish the area. These assets provided not only visual support but also served as a scale reference for the bath. In rendering the final design, the props were removed and the render relied more heavily on the scene set-up to enhance the aesthetic qualities of the bath unit.

Key to the visual appeal of the renders was the use of appropriate lighting and camera features. Most of the scenes within the original concept renders were done using a manually adjusted three-point lighting scheme common in studio photography. The renders of the final design on the other hand did not use this lighting scheme. Set within an enclosed room, the lighting added was representative of real-world lighting fixtures that would likely exist within a small bathroom, resulting in only a single overhead light source. Ultimately, this preparatory work within the render scenes meant that almost no post-process editing was needed. Only certain elements such as water were added in post processing using Adobe Photoshop.

Conclusions

Conceptually this project has had many iterations during its development. Although the idea of a folding bath is one that is attractive to the small home owner, limitations in how materials can be designed to fulfill this purpose effectively have prevented it from becoming a mainstay of bathroom design. The original Sirna Panel concept does save space in the bathroom when not in use, but the amount of space and effort needed to deploy the bath would likely discourage regular use. With the design change to the fixed size bath, a halfway solution between a standard bath and shower unit is achieved, providing the benefits of both.

The final design shown here does not however fully fill the design spec. In its current state, the design would be financially prohibitive for the intended target market. Liberal use of intensely machined timber panels would drive the unit price dramatically. As such, the concept can be considered an aesthetic ideal. To properly bring the design to market, it would require the simplification of the entire unit. An entry level model would likely be composed of cheaper plastics and remove the decorative timber panels. This would reduce price levels and also provide the benefit that the bath would more readily fit into the interior décor of today’s modern homes.

References

Koch, W. (2013). Mini-apartments are the next big thing in U.S. cities. [online] Usatoday.com. Available at: http://www.usatoday.com/story/news/nation/2013/07/30/tiny-apartments-apodments-catch-on-us-cities/2580179/ [Accessed 8 Dec. 2014].

Lofquist, D., Lugaila, T., O'Connell, M. and Feliz, S. (2012). Households and Families: 2010. 1st ed. [ebook] U.S. Department of Commerce. Available at: http://www.census.gov/prod/cen2010/briefs/c2010br-14.pdf [Accessed 9 Jan. 2014].

National Aeronautics and Space Administration, 1995. ANTHROPOMETRY AND BIOMECHANICS. [online] Available at: http://msis.jsc.nasa.gov/sections/section03.htm [Accessed 5 Jan. 2014].

Mayor Bloomberg Announces Winner Of adapt Nyc Competition To Develop Innovative Micro-unit Apartment Housing Model, 2013. Available at: http://www1.nyc.gov/office-of-the-mayor/news/032-13/mayor-bloomberg-winner-em-adapt-nyc-em-competition-develop-innovative-micro-unit#/0. [Accessed 22 Oct. 2013]

Mukherji, A. (2014). Are Micro-Apartments Legal?. [online] Boston Real Estate Law News. Available at: http://bostonrealestatelawnews.com/2014/02/are-micro-apartments-legal.html [Accessed 26 Mar. 2014].

Renovation in America, Findings from the 2013 Houzz & Home Survey. (n.d.). 1st ed. [ebook] Houzz. Available at: http://info.houzz.com/rs/houzz/images/Houzz%20%26%20Home%202013%20Report.pdf [Accessed 13 Jan. 2014].

US Census Bureau, 2010a. 2010 Census Urban Lists Record Layouts. Available at: http://www.census.gov/geo/reference/ua/ualists_layout.html. Accessed: [05/01/2014]

US Census Bureau, 2010b. 2010 Census Urban and Rural Classification and Urban Area Criteria. Available at: http://www.census.gov/geo/reference/ua/urban-rural-2010.html. Accessed: [04/01/2014]

US Census Bureau, 2010c. 2010 Census Urban Area FAQs. Available at: http://www.census.gov/geo/reference/ua/uafaq.html. [Accessed: 04/01/2014]

Statistical Abstract of the United States: 2012. (2012). 1st ed. [ebook] U.S. Census Bureau, p.629. Available at: https://www.census.gov/compendia/statab/2012/tables/12s1003.pdf [Accessed 3 Jan. 2014].

Wood-database.com, (n.d.). Western Red Cedar | The Wood Database - Lumber Identification (Softwoods). [online] Available at: http://www.wood-database.com/lumber-identification/softwoods/western-red-cedar/ [Accessed 9 Nov. 2013].

Bibliography

Black, A. and Murata, N. (2000). The Japanese house. 1st ed. London: Scriptum Editions.

Brown, A. (2012). The very small home. 1st ed. New York: Kodansha USA.

Colman, P. (1994). Toilets, bathtubs, sinks, and sewers. 1st ed. New York: Atheneum Books for Young People.

Smith, B. and Yamamoto, Y. (2012). The Japanese bath. 1st ed. Salt Lake City, Utah: Gibbs Smith.

Talmadge, E. (2006). Getting wet. 1st ed. Tokyo: Kodansha International.